Timber Shell Structures

The project attempted to challenge the conception of wood as it is currently used to experiment further with this sustainable material. The ability to create novel forms and structures has outpaced our ability to realize these forms with the materials we conventionally use. The ability of wood to flex and create curved forms and its machinability make it an ideal material for realizing the new experimental forms of architecture today. The work demonstrated the feasibility of constructing curved laminated wood shell structures.

Use of off-axis samples

For brittle materials such as wood under tension and shear loading, statistically based size effects on strength are adequately explained by theories such as the Weibull theory. The material parameters needed to formulate a failure criterion can be determined according to standard tests on samples exhibiting radically different shapes and volumes. An increase of accuracy can be obtained by using a less disparate set of tests to determine the material strengths; e.g. with off-axis samples that are identical in geometry and volume, and allow formulating failure criteria more straightforwardly.

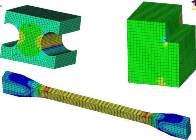

Welding of wood

Linear vibration welding timber structural elements provides new opportunities to potentially achieve structural joints. This project investigated to which extent welding of wood can be considered for load bearing structural joints. On the basis of a series of experimental and numerical investigations, failure modes were identified and the associated failure criterion was quantified. A probabilistic method subsequently allowed accurately predicting the capacity of the tested wood welded joints based on objective input data, including an estimate of the scattering due to the material’s inherent variability.

Comparison of small specimen test methods

The project investigates the problematic of determining Weibull parameters on solid and glue-laminated wood specimens using off axis samples. The procedure is compared to the alternative, i.e. determining the mechanical parameters according to ASTM-D143 on samples with different shapes and volumes. The advantages using off-axis tests are clearly shown in the examples.

Improved visual sorting procedures for glulam lamellas

At the Bern University of Applied Sciences, I was involved in a project on developing an integrated production chain to optimize glued laminated timber in Switzerland in corporation with sawmills, grading machine producers, manufacturers, the University Karlsruhe, ETH Zürich and the Swiss Institute for Material Testing.

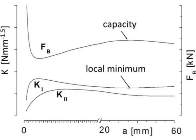

Fracture mechanics approach to dowel type fasteners

In my graduating theses, I studied the load bearing capacity of mechanical joints in timber perpendicular to the grain with dowel-type fasteners using Linear-Elastic-Fracture Mechanics. I applied a routine of calculating the stress intensity factors (SIF) and modeled the loaded timber elements and the typical development of the SIF in dependence of crack lengths. I studied the influence of geometrical and loading parameters of the mechanical joint and defined a critical crack length as the length where the crack becomes unstable. Ultimately, it was possible to formulate a design equation to estimate the load bearing capacity of single dowel joints.